When you consider reducing-edge technological know-how in production, among the initially things that possibly involves head may be the laser chopping machine. These incredible units are revolutionizing how industries approach precision and performance. Whether or not It can be for creating intricate models or just slicing by way of tricky components, a laser cutter can handle everything easily. The magic of laser chopping technological innovation lies in its capability to give superior precision and versatility. Visualize a laser cutter as a substantial-tech sculptor, carving out shapes Together with the precision of a skilled artisan.

Laser cutters, or CNC laser slicing equipment, are significantly noteworthy for his or her exacting benchmarks. As opposed to traditional reducing solutions that may be imprecise and labor-intense, CNC laser reducing automates the procedure, reducing human mistake and increasing productiveness. This technological innovation utilizes Computer system numerical Manage (CNC) to guideline the laser, guaranteeing that every cut is executed precisely as planned. It's akin to using a robotic which has a ruler, ensuring every element of one's layout is ideal.

The Of Laser Cutting Technology

Industrial laser slicing has built sizeable strides through the years, evolving from primary versions to hugely subtle programs capable of managing a range of elements. Industrial applications range from automotive factors to aerospace elements. The flexibility of industrial laser cutters helps make them indispensable in several sectors. Consider them given that the Swiss Military knives on the production earth—adaptable and indispensable.

Industrial laser slicing has built sizeable strides through the years, evolving from primary versions to hugely subtle programs capable of managing a range of elements. Industrial applications range from automotive factors to aerospace elements. The flexibility of industrial laser cutters helps make them indispensable in several sectors. Consider them given that the Swiss Military knives on the production earth—adaptable and indispensable.One of the more fascinating facets of laser slicing technology is its precision. When we talk about precision laser cutting, we're referring to the flexibility of those machines to attain extremely restricted tolerances. By way of example, some laser cutters can develop parts with tolerances as restricted as 0.one mm. This volume of precision is important for industries in which just about every millimeter counts, such as in electronics or medical device production. It truly is like drawing using a pencil that under no circumstances wavers from the line.

The 7-Minute Rule for Laser Cutting Technology

The equipment Utilized in laser chopping systems is often very elaborate, however it’s the Sophisticated attributes that make them so highly effective. Modern day laser cutting tools often features sophisticated cooling systems, superior-driven lasers, and automated loading and unloading mechanisms. These characteristics lead to your machine's efficiency and longevity, guaranteeing that businesses get the most out of their investment. Visualize a nicely-oiled machine that’s generally prepared to complete at its best—that’s what large-quality laser slicing equipment delivers.

The equipment Utilized in laser chopping systems is often very elaborate, however it’s the Sophisticated attributes that make them so highly effective. Modern day laser cutting tools often features sophisticated cooling systems, superior-driven lasers, and automated loading and unloading mechanisms. These characteristics lead to your machine's efficiency and longevity, guaranteeing that businesses get the most out of their investment. Visualize a nicely-oiled machine that’s generally prepared to complete at its best—that’s what large-quality laser slicing equipment delivers.For anyone from the sheet metal marketplace, a sheet metal laser cutter is a sport-changer. Common ways of chopping metal sheets might be cumbersome and imprecise, but laser cutters excel During this area. They supply cleanse cuts and intricate models without the will need For extra ending. This not simply hastens output but will also enhances the general good quality of your concluded product or service. Photograph a sculptor that has a wonderful-tuned chisel—This really is how laser cutters get the job done with sheet metal.

Laser reducing products and services have become more and more well-liked for corporations trying to outsource their reducing needs. These expert services present usage of advanced laser slicing know-how with no will need for significant upfront investment decision. It’s like leasing a luxurious motor vehicle for each day—you have to take pleasure in the advantages with no extensive-time period motivation. These companies can manage every thing from compact prototype runs to large production batches, earning them a versatile Resolution For a lot of industries.

When we discuss laser reducing units, we’re referring towards the extensive setup that features the laser cutter by itself, Command units, and sometimes software package for coming up with and handling cuts. These units are intended to perform seamlessly jointly to create high-good quality benefits. Think of it being a very well-orchestrated symphony wherever each part plays an important purpose in obtaining the final masterpiece. The mixing of those components is key to maximizing efficiency and precision.

Precision in laser reducing isn’t nearly precision; it’s also about consistency. Laser slicing devices preserve the same level of precision throughout every single Lower, ensuring that each aspect is identical to the final. This consistency is vital for industries explore here wherever uniformity is vital, including in production elements for electronics or automotive elements. It’s like getting a meticulous craftsman who by no means misses a conquer.

Some Known Questions About Laser Cutting Equipment .

In terms of technological improvements, laser slicing continues to evolve. New developments in laser chopping engineering are read now creating these devices a lot quicker, additional effective, and able to handling all the more sophisticated tasks. Innovations including fiber lasers and hybrid techniques are pushing the boundaries of what’s probable. It’s like upgrading from the smartphone to some reducing-edge machine with options you didn’t even know you desired.Laser reducing full details equipment is usually really an financial investment, even so the return on investment decision (ROI) is commonly substantial. The performance, precision, and lessened squander linked to laser slicing indicate that businesses can see considerable Charge financial savings after some time. It’s a little like investing in a substantial-top quality Device that will save you effort and time In the long term. The initial expense may be offset with the gains in productivity and good quality.

Get This Report about Laser Cutting Services

For industries that need intricate types and higher levels of customization, laser reducing technological know-how is often a aspiration arrive genuine. The chance to generate intricate designs and detailed components with out sacrificing good quality is usually a video game-changer. Regardless of whether you’re designing personalized parts for equipment or crafting intricate ornamental things, laser cutters present unparalleled adaptability and precision.

The environmental advantages of laser slicing are also well worth noting. Since laser cutting is so precise, it typically results in significantly less content squander when compared to conventional reducing approaches. This precision not just aids in decreasing costs but will also minimizes the environmental effects. It’s like using a laser scalpel as an alternative to a blunt knife—much more efficient and less wasteful.

In conclusion, laser reducing machines and technological innovation signify a major improvement in manufacturing and style. Whether you’re looking at industrial laser cutting, CNC laser reducing, or specialised sheet metallic purposes, the benefits are very clear. With precision, efficiency, and suppleness, laser cutters are paving the way for the way forward for manufacturing. So subsequent time you marvel at a perfectly crafted component or possibly a wonderfully designed piece, don't forget there’s a great possibility a laser cutter built it probable.

Alicia Silverstone Then & Now!

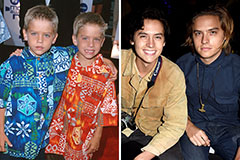

Alicia Silverstone Then & Now! Dylan and Cole Sprouse Then & Now!

Dylan and Cole Sprouse Then & Now! Sydney Simpson Then & Now!

Sydney Simpson Then & Now! Nancy Kerrigan Then & Now!

Nancy Kerrigan Then & Now! Tina Majorino Then & Now!

Tina Majorino Then & Now!